Mapping the flow of your mold’s water circuitry is key to process control and troubleshooting

There are many factors that can lead to process inconsistency, and mold watering is a key factor in process control. Temperature variations in tooling are not only detrimental to process control, but can also lead to tool damage. Hot spots in a mold can cause premature tool wear, and in some cases mold damage.

Even in a plant with treated water, scaling of mold circuits can occur. Treatment processes have improved over the last decade, but they still do not act as a complete fail-safe against the potential of decreased water flow.

This article will outline key measurables within the mold watering system, as well as define how to use this data to identify water issues. By measuring this data with the mold in a good running state. This provides the opportunity to troubleshoot changes within the mold watering schematic.

Turbulent Flow: Best described as the rolling and churning action of water, turbulent flow is a primary driver of mold temperature consistency. Increased turbulent flow helps to spread the performance of water circuits while improving temperature consistency across mold surfaces and components. Poor turbulence leads to mold hot spots and temperature fluctuations.

Primary methods of measuring turbulent flow are Gallons/ Liters per minute, as well as measuring the pressure drop. This data is recorded for each circuit of the mold, and the data is saved for future referencing.

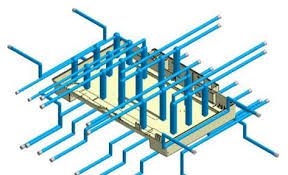

Circuit Identification: When mapping mold circuits, it is imperative that each circuit be labeled by both a number exclusive to the circuit, as well as supply or return designation. For example, “ 1 IN- 1 OUT, 2 IN, 2 OUT”. Direction of flow is key to mold mapping. Baffles require water to flow in a specific direction, and cascades can also be receivers of build up that when water flow is reversed, poor turbulence and hot spots can occur.

GPM: Measuring the amount of water passing through the mold every minute is a key measurable in determining turbulent flow. Higher numbers assure that water flow is adequate, and that turbulent flow is at an acceptable level. Minimum turbulent flow would be 12-14 GPM, while numbers in the 20’s would be identified as an excellent flow rate.

Pressure Drop: Drops in pressure are another key measurement in turbulent flow. Pressure drop is determined by measuring pressure as the water enters the circuit. This is then compared to water pressure as the water exits the circuit. If the water exiting is too close in pressure, flow resistance is low and turbulence is impeded by passing too easily through the circuit. Pressure drop can be increased by using smaller lines on the return side of the mold. Changes in pressure on either side can also point towards a problem with the water system, or a poorly performing thermolator.

Mapping the circuitry of your mold is crucial in water troubleshooting events. By properly recording water data, your company improves its ability to pinpoint changes within the mold watering system. Historical data is a molder’s best defense against changes within the process control schematic.

For more information, fill in the form below and we will be happy to assist you!